| Ident System carries a range of specialized and standard RFID tags on stock, or in some cases as made to order to adapt to our customer’s system. We will present a few of our most common tags here, but you might want to contact us to find the tag best suited for your specific needs. |

|

| When you want positional data for a forklift in the loading dock or factory floor to ensure that the load is taken to and from the right place, use our floor tag. The floor tag is part of a 125 kHz LF system and designed to be embedded in the floor – out of the way. All that is needed is to drill a small hole, drop in the tag, and refill the hole. Tag dimensions are 105 x 16 (diameter) mmWe typically install our Ideal125 LF reader in the forklift, connected to its terminal wich forwards the positional data to the WMS, etc. The antenna is mounted under the forklift. |

|

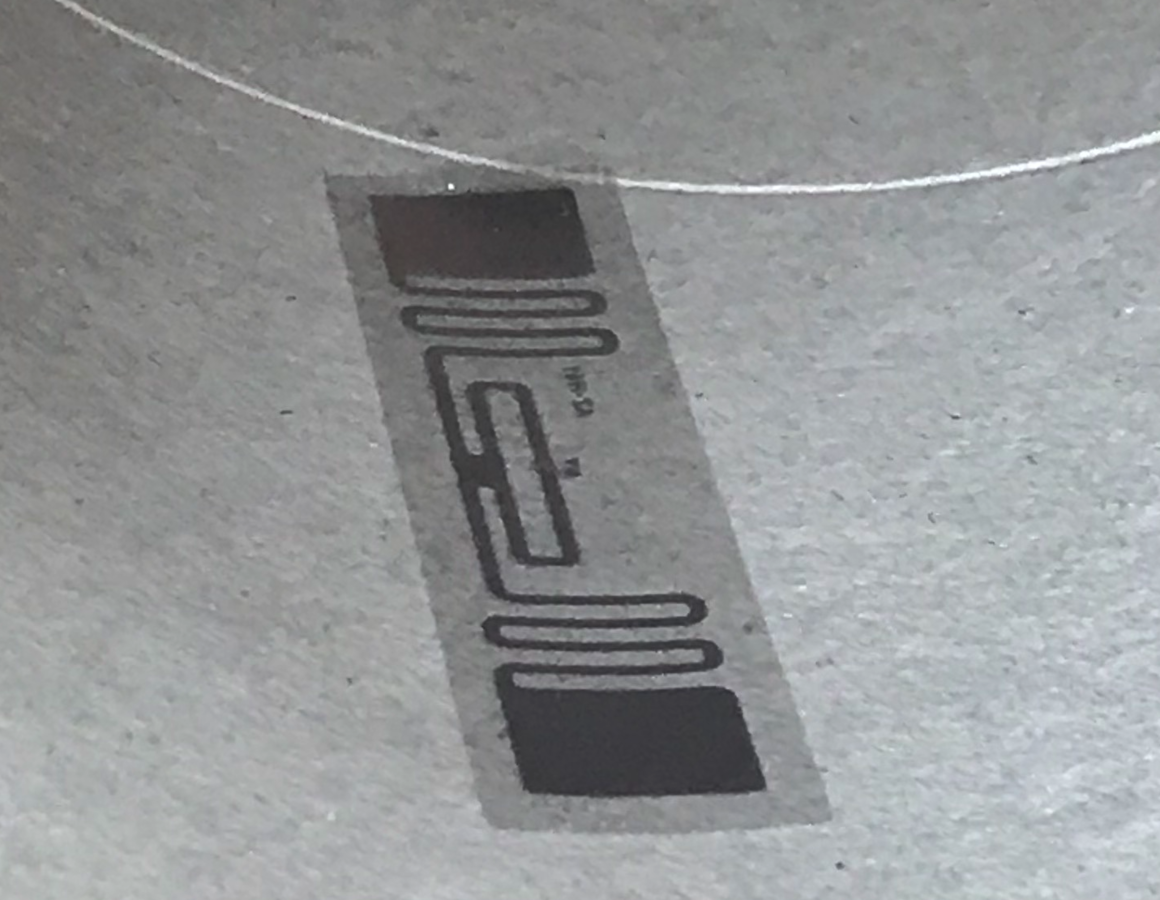

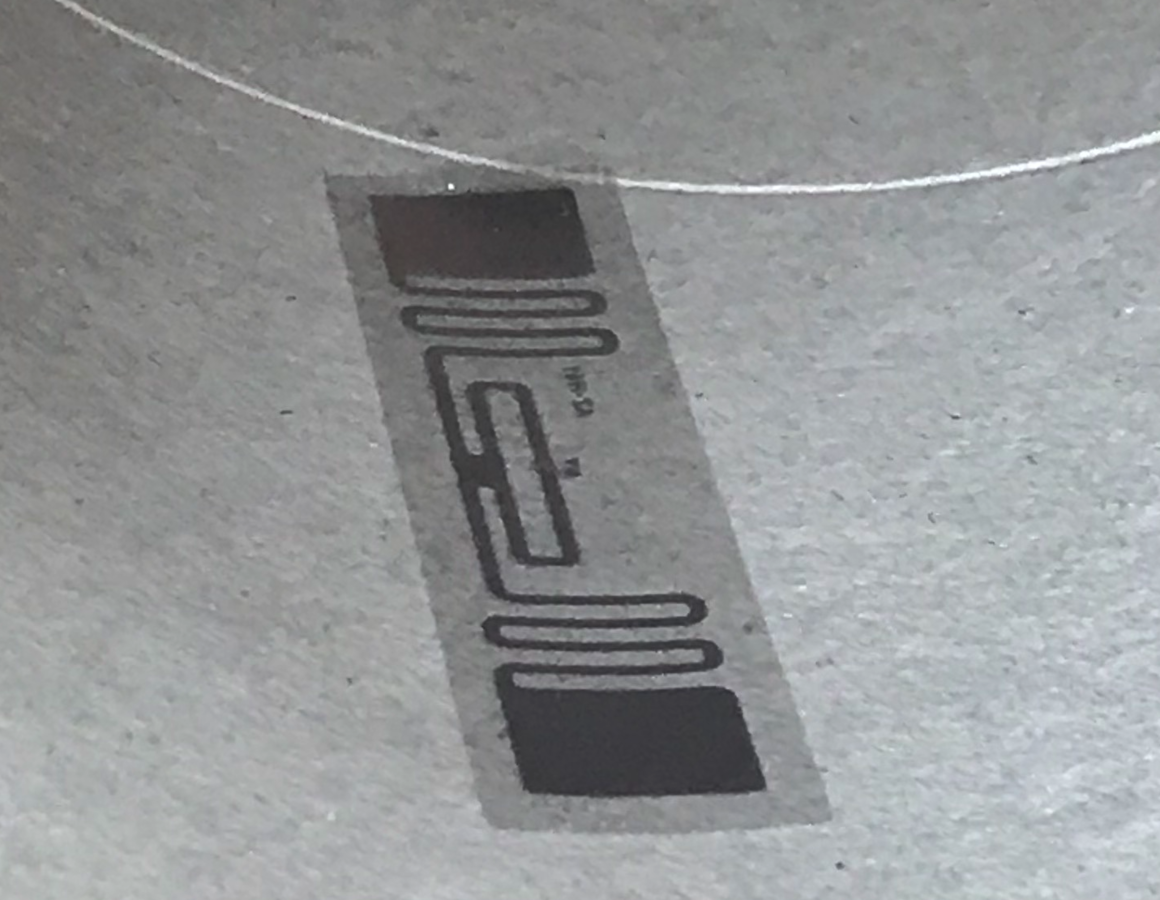

| For the packaging industry that manufactures for food and beverages companies, we have a UHF wet inlay tag suited for mounting inside the carton rolls. |

|

| We also have an LF 134.2 kHz tag especially developed for ID of Tambours in the paper industry. This tag is especially developed to handle the high demands of ruggedness and good readability when placed against a metal surface. |

|

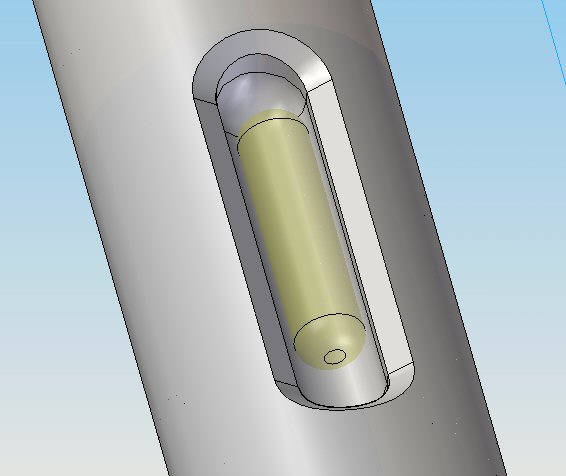

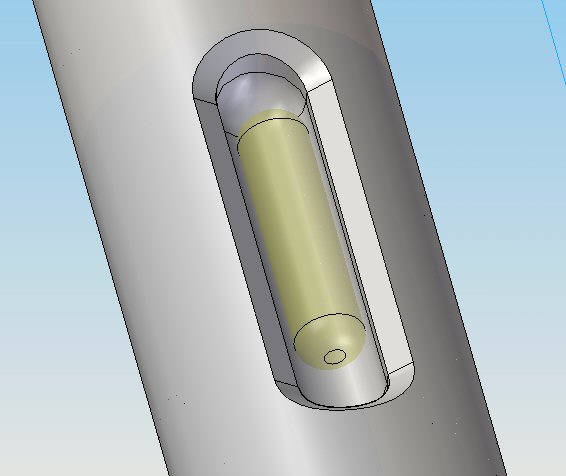

| For tracking of tool (drills, milling machines etc) auto-selection and wear, we have a miniature glass tag working at 125 kHz. This is placed inside a milled slot in the tool and is ideally read by our handherld reader USB125 or similar. |

|

| For customers that still use the pc3103/xx (OIS-P) tags from Identec solution (Baumer) wich production were closed down in 2018, we offer customers a refurbishment program that makes the tags as new.The refurbishment program includes: – exchange of battery = prolonged lifetime – test of tags functions – test of micro wave functions. – The program is based on a minimum tag volume of 20 pc per batch or more.We can also offer a wide range of cable ties with LF/HF/UHF tags from HellermannTyton. |

Paper industry

Ident System AB – Our RFID tags

| Ident System carries a range of specialized and standard RFID tags on stock, or in some cases as made to order to adapt to our customer’s system. We will present a few of our most common tags here, but you might want to contact us to find the tag best suited for your specific needs. |

|

| When you want positional data for a forklift in the loading dock or factory floor to ensure that the load is taken to and from the right place, use our floor tag. The floor tag is part of a 125 kHz LF system and designed to be embedded in the floor – out of the way. All that is needed is to drill a small hole, drop in the tag, and refill the hole. Tag dimensions are 105 x 16 (diameter) mmWe typically install our Ideal125 LF reader in the forklift, connected to its terminal wich forwards the positional data to the WMS, etc. The antenna is mounted under the forklift. |

|

| For the packaging industry that manufactures for food and beverages companies, we have a UHF wet inlay tag suited for mounting inside the carton rolls. |

|

| We also have an LF 134.2 kHz tag especially developed for ID of Tambours in the paper industry. This tag is especially developed to handle the high demands of ruggedness and good readability when placed against a metal surface. |

|

| For tracking of tool (drills, milling machines etc) auto-selection and wear, we have a miniature glass tag working at 125 kHz. This is placed inside a milled slot in the tool and is ideally read by our handherld reader USB125 or similar. |

|

| For customers that still use the pc3103/xx (OIS-P) tags from Identec solution (Baumer) wich production were closed down in 2018, we offer customers a refurbishment program that makes the tags as new.The refurbishment program includes: – exchange of battery = prolonged lifetime – test of tags functions – test of micro wave functions. – The program is based on a minimum tag volume of 20 pc per batch or more.We can also offer a wide range of cable ties with LF/HF/UHF tags from HellermannTyton. |

Complementing your TambourID system with our handheld USB reader.

If you have our 134.2 kHz TambourID system installed you might at times have run into a situation when you wanted to read the RFID tag installed on the tambour, but not had any other means to do this except for the fixed installed antennas. You might have suspected that the antenna or reader didn’t perform as it should, or that the tag was damaged and wanted to confirm the TagID or its function through in some additional way.

IdentSystems handheld USB reader can handle the TambourID tags and several other tags in the LF (125/134.2 kHz) range. It can be connected to your normal PC via USB and tag ID is read into the PC for verification. Our USB reader is also powered through the USB port, so no external power is necessary.

The USB reader can, of course, be used in other situations than the TambourID, it is suitable for a range of tags in the 125/134.2 kHz range, so have a look at our international site for details, www.identsystem.com.

If you are from Sweden you can also purchase the reader from our webshop.

Custom antennas for 125 and 134,2 kHz systems

At Ident System AB we can design and manufacture both standard and custom models of inductive antennas suited for most 125 amd 134,2 kHz systems, including Baumers OIS-L.

For more information, get in touch with your regular contact at Ident System AB, or by email on info@identsystem.com.

OIS-P PC3040 with IdentSystem Tambour ID

If you today are running an old OIS-P PC3040 system, we want you to know that it is possible to upgrade or complement it with our new, modern Tambour ID system IDeal134.

The installation can be done without any other units or reprogramming of your current system.

For more information, get in touch with your regular contact at Ident System AB, or by email on info@identsystem.com.

More features in our Signal Interface Converter

A couple of weeks ago we introduced our EVS Signal Interface Converter (EVS-SIC) as our next product in a series of new releases where refocus on increasing the life and compatibility of your existing system.

That release was focusing on presenting the Serial Interface Conversion aspect of the Converter, but it has a second function.

By connecting the USB port to your trucks (or other devices) USB port, our EVS-SIC can act as a keyboard emulator instead of Signal Converter. This mean that a readers (RFID, Barcode) output when connected to the input of EVS-SIC can be transferred to a truck terminal as if typed on a keyboard.

As for the serial data conversion, the connection is made through standard RS232 interfaces both in and out, and the transfer rate on both ports can be selected between 1.200 to 115.200 kbit/s. Parity and/or Stop bits can also be converted.

The EVS-SIC can also be used for logic control, i.e. the unit can be programmed with a databse for verification of approved ID numbers, which are either used for verification that the tag is correctly read, or for control purposes of a connected unit.

Note that EVS-SIC can only be used as Signal Converter or keyboard emulator, not both simultaneously.

Use your old equipment with our modern EVS138 readers

We continue this year by presenting our next product in a series of new releases where refocus on increasing the life and compatibility of your existing system.

After Introducing our ZIOX-converter in our RFID line last year, we now present our EVS Signal Interface Converter (EVS-SIC)

You might want to keep your existing camera in a code reading system, while still needing to upgrade the readers to more modern technology. As always when merging new technology with old, there might be problems with communication between the units.

A common case we have seen is when a customer want to switch to our EVS138 readers while preferring to keep their old Baumer EVS128 or EVS134 cameras. Our EVS138 reader communicate via a 115.200 kbit/s interface, while the Baumer camera send its data at 12.000 kbit/s. By connecting our EVS-SIC between the units, the signal is converted seamlessly.

The EVS-SIC can of course be used for any kind of serial data conversion. The connection is made through standard RS232 interfaces both in and out, and the transfer rate on both ports can be selected between 12.000 to 115.200 kbit/s. Parity and/or Stop bits can also be converted.

RFID-based Tambour-ID

Since the launch of our Ideal134 system, IdentSystem AB have now made our 5th installation globally of the system for use for Tambour ID at papermills.

The system fully replaces the older Baumer Ident OIS-P and it can also be used for new installations. Ideal134 give the user full traceability back to master systems such as MES and similar and is invaluable for operators to avoid errors in handling and to trace production and quality data.

The system consists of a reader connected to the present Mill Executive System and will keep track of Tambour-ID, orientation and acceptable destinations. The Tambour-ID system easily integrates with various MES e.g. Honeywell Optivision, ABB Automation, Paperline and similar systems.

We have put together a short system description of our Tambour-ID solution that can be downloaded from our website here: Link to Tambour-ID pdf.

Upgrade to LF-RFID for better performance in paper industry

Tambour identification has in the past mostly been done using Microwave-based systems. That hardware is now getting to a point where it needs to be replaced in order to warrant a safe and trouble-free operation in the mills. Since a few years Ident System AB offers an economic and well-proven replacement system based on LF-RFID instead of the microwave systems.

The system consists of a reader connected to the present Mill Executive System and will keep track of Tambour-ID, orientation and acceptable destinations. The Tambour-ID system easily integrates with various MES e.g. Honeywell Optivision, ABB Automation, Paperline and similar systems.

Ident System AB has in the past years successfully installed well over 30 systems and more are on the way. The customers have greatly appreciated the quick and easy installation and the good performance of the systems.

Ident System AB has put together a short system description of our Tambour-ID solution that can be downloaded from our website here: Link to Tambour-ID pdf.

Ident System AB – More than just Products

In our efforts to be a full-spectrum partner for your automatic identification services needs, Ident System AB tries to provide everything you need from pre-purchase analysis and consulting, to installation and following support needs.

We take full responsibility for our products and systems by providing the level of support you requite during the whole implementation process as well as ongoing service and support to ensure your problem-free operation.