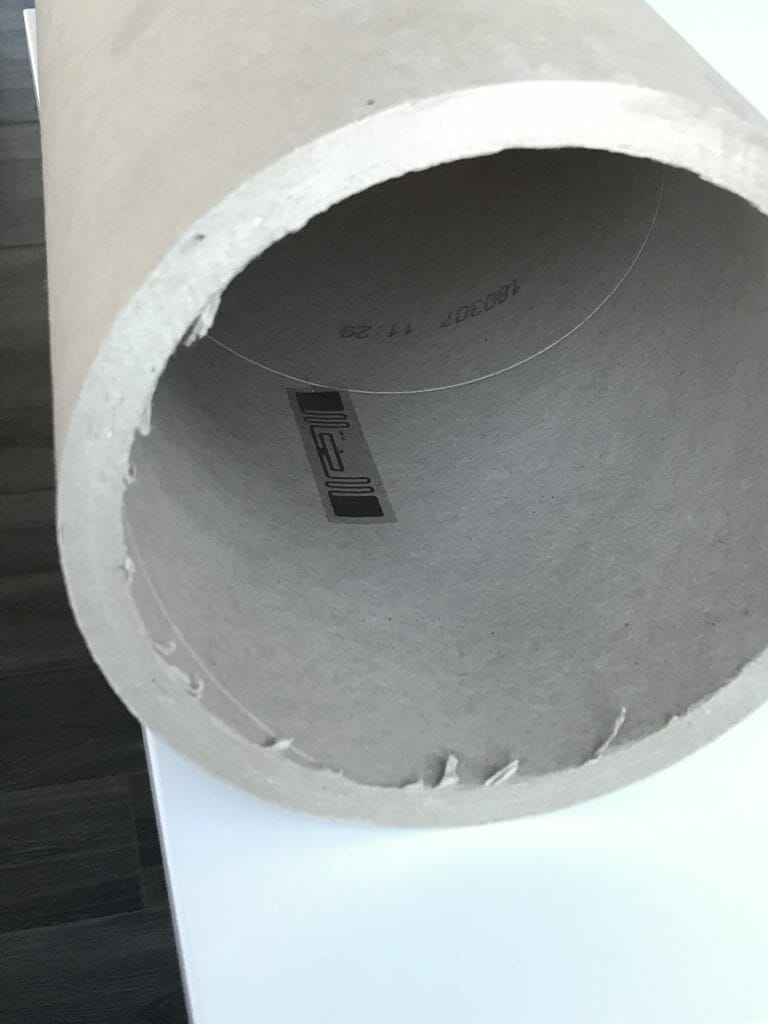

For use in the paper packaging industry, IDent System AB has designed an UHF-based system for tracking the paper rolls through the process. Starting from when the tambours are cut down to size for production, the tags are inserted automatically by the cutting machine and will then stay in place until the roll is emptied, allowing complete traceability through the whole process form papermill to the finished packaging.

This particular case is for drink containers, and the tags are tested and approved for use in food industry.

Since the roll has been identified through all its manufacturing steps in the paper mill by its TambourID, by tagging the roll as it is cut up, it is possible to track the roll back through the original paper-making process at the paper mill – especially important in the controlled food industry.

When it arrives at the printer – all data about printing, lamination and other processes will be added to the information and when the final product – a filled drink package leaves the plant, it can later be traced back all the way through manufacturing by connecting its barcode to the roll in case of for example quality issues where traceability is very important.

Naturally, the TambourID, UHF system and final barcodes will also be used to control the logistics flow, and specify how the tambour should be cut, how the individual roll should be printed/treated as well as what package it’s being prepared for.