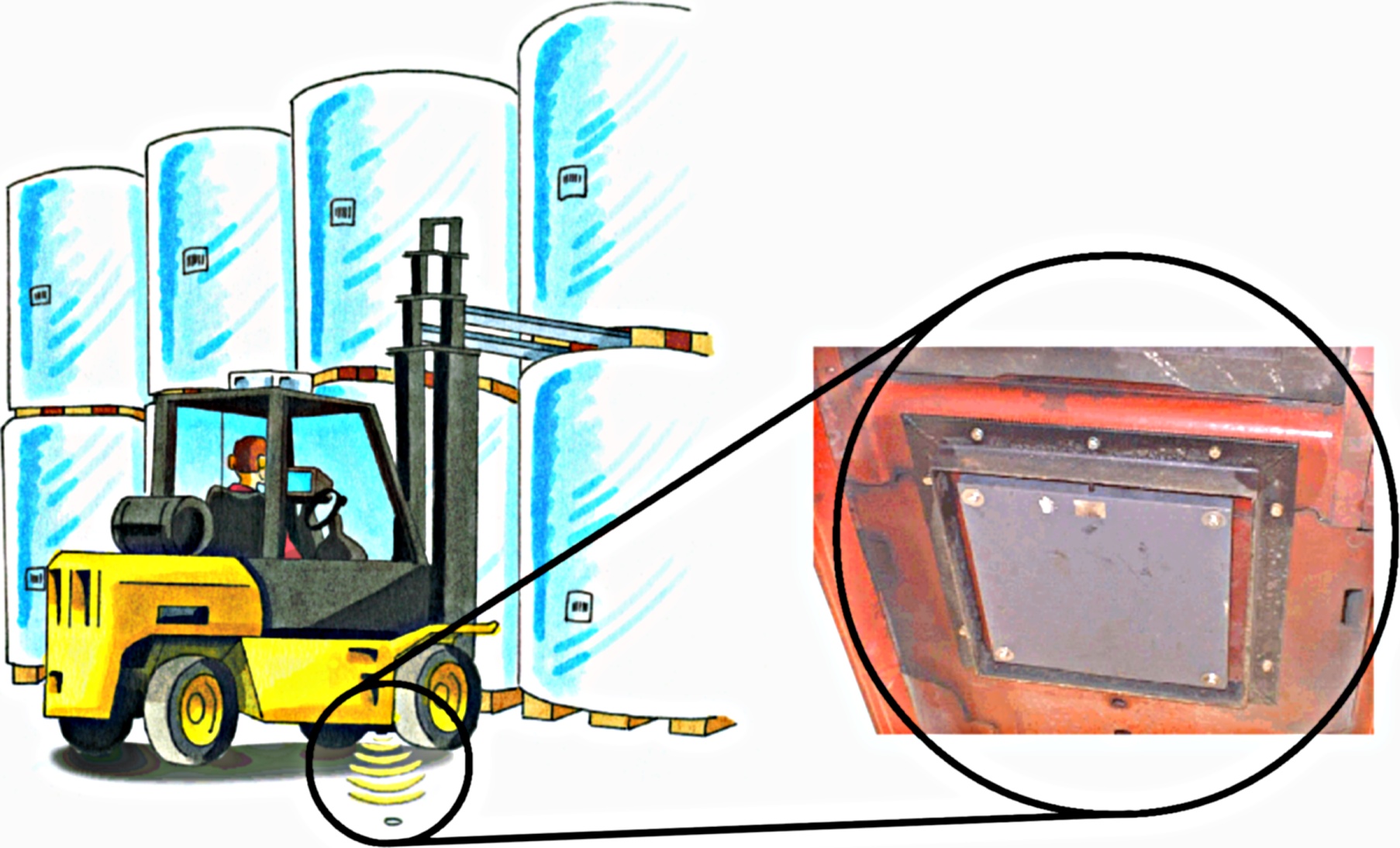

This week we wanted to present one of our RFID solutions that we have got many questions about. It is the use of our IDEAL134 LF-RFID reader mounted on a forklift to control its position when picking up and/or delivering pallets, for example from a storage location to a container for further shipping.

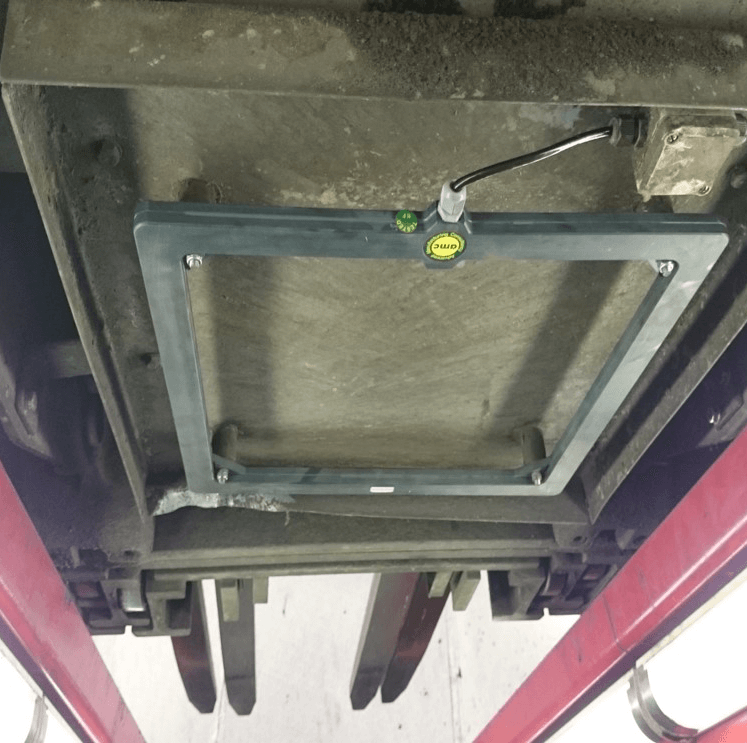

The location data will be collected through a tag that is embedded in the concrete floor at the container location, or the storage space, and is read by a custom antenna mounted below the forklift. Pick-up and delivery location can then be read on the forklift’s onboard screen or sent on to a WMS.

Our own RFID products and systems suitable for the logistics industry are mainly working in the LF range (125kHz). This range relatively insensitive to its surroundings, working around both water, metal, ice and snow. Reading distances are typically within 50cm which naturally reduces the risk of cross-reading another tag in the vicinity. Another advantage is that the range is less regulated and antennas can be custom made to fit a specific application without needing to be tested and approved – thus allowing a high flexibility in antenna design.We do however also help out customer to whole systems, built around what is best for their application – there are after all times when a HF or UHF system is better suited to solve a particular problem.

Regarding the RFID tags, we have a large assortment of LF and other tags among our products, such as encapsulated tags for embedding in a concrete floor, small glass tags to embed in tools and machinery, UHF sticker tags for labeling of singer products or packages, even for use in the food industry. We have also tags suited for mounting on a piece of machinery or service location, that is scanned to document when the item is serviced controlled.