| Ident System carries a range of specialized and standard RFID tags on stock, or in some cases as made to order to adapt to our customer’s system. We will present a few of our most common tags here, but you might want to contact us to find the tag best suited for your specific needs. |

|

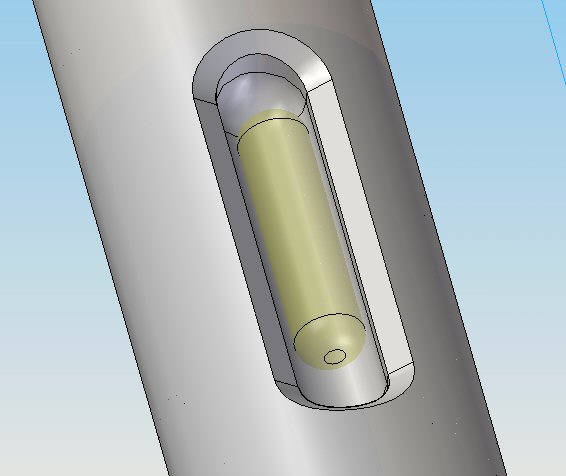

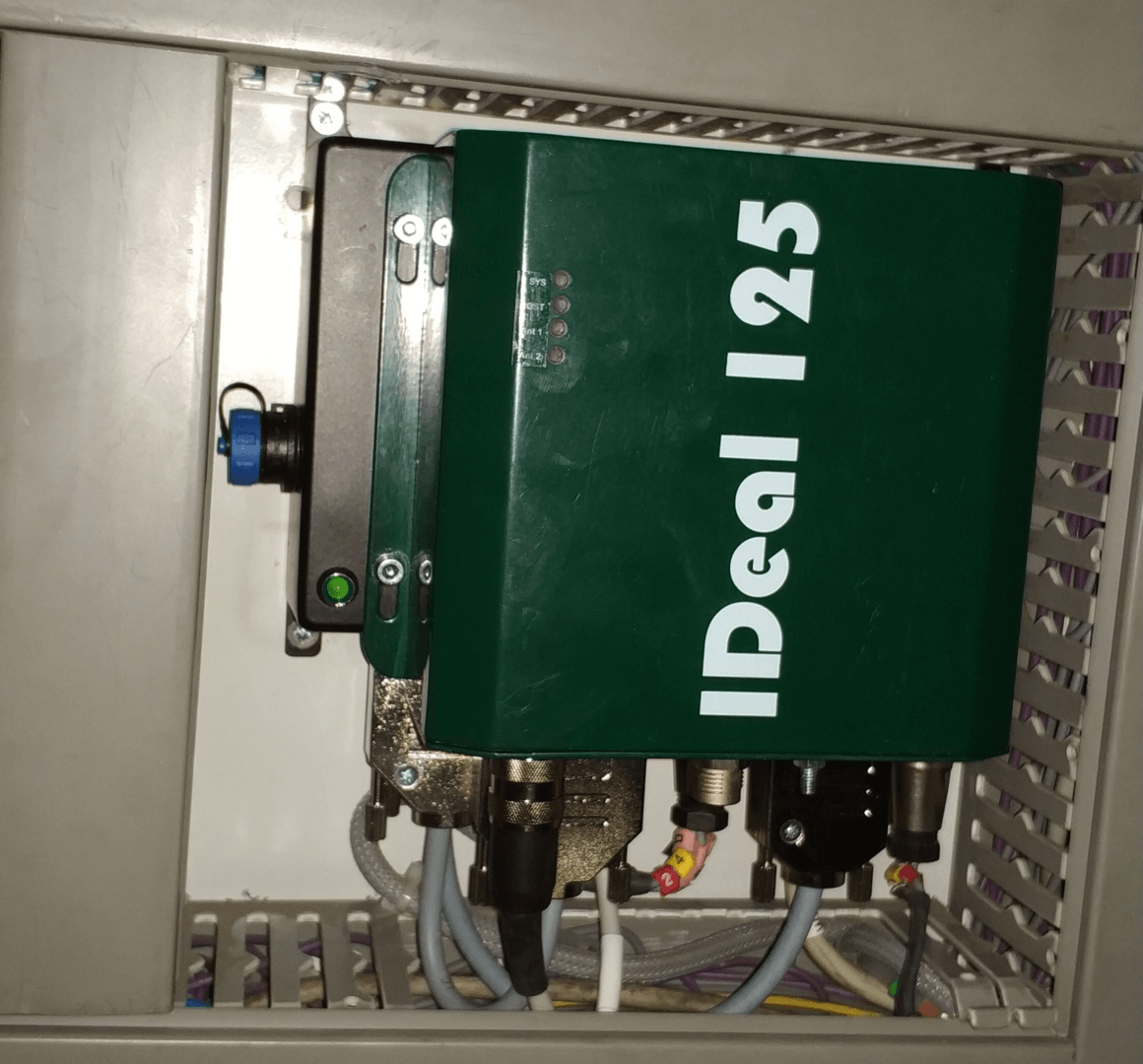

| When you want positional data for a forklift in the loading dock or factory floor to ensure that the load is taken to and from the right place, use our floor tag. The floor tag is part of a 125 kHz LF system and designed to be embedded in the floor – out of the way. All that is needed is to drill a small hole, drop in the tag, and refill the hole. Tag dimensions are 105 x 16 (diameter) mmWe typically install our Ideal125 LF reader in the forklift, connected to its terminal wich forwards the positional data to the WMS, etc. The antenna is mounted under the forklift. |

|

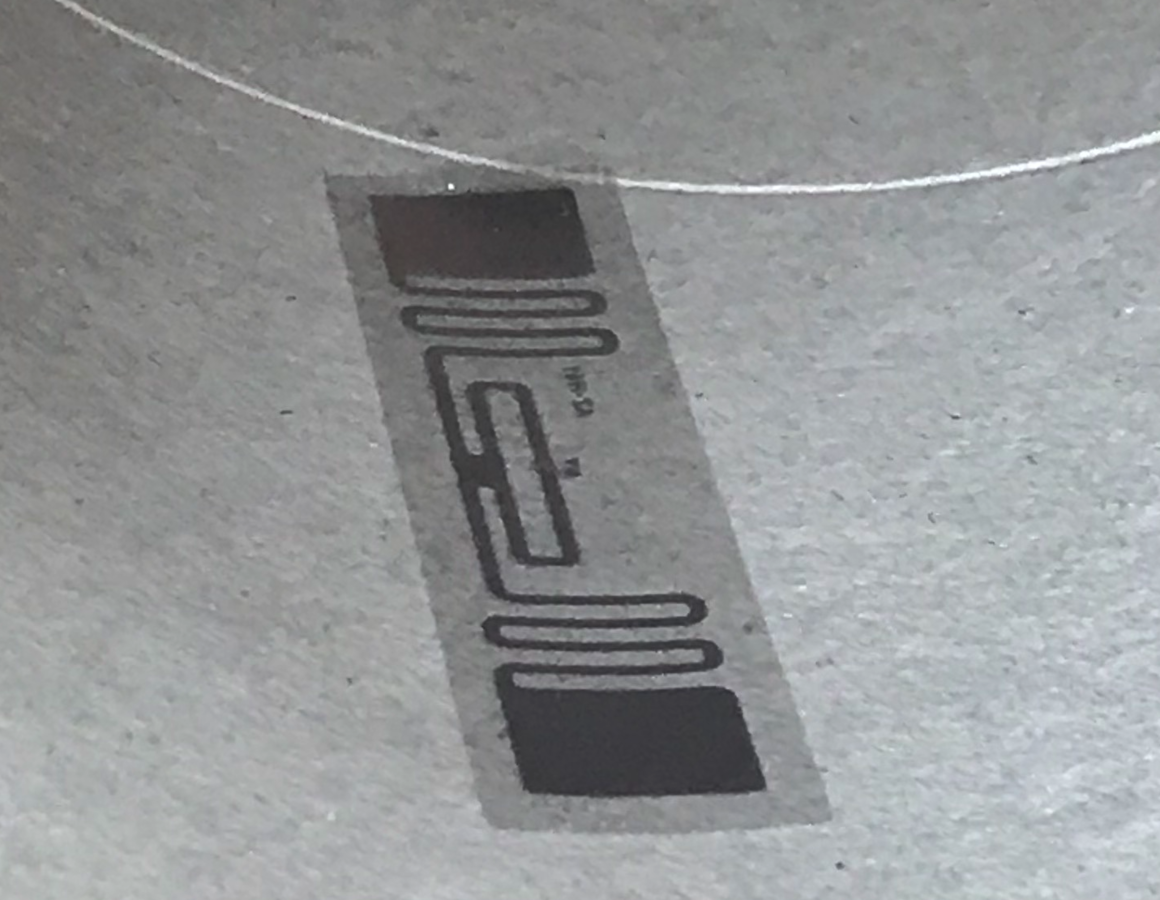

| For the packaging industry that manufactures for food and beverages companies, we have a UHF wet inlay tag suited for mounting inside the carton rolls. |

|

| We also have an LF 134.2 kHz tag especially developed for ID of Tambours in the paper industry. This tag is especially developed to handle the high demands of ruggedness and good readability when placed against a metal surface. |

|

| For tracking of tool (drills, milling machines etc) auto-selection and wear, we have a miniature glass tag working at 125 kHz. This is placed inside a milled slot in the tool and is ideally read by our handherld reader USB125 or similar. |

|

| For customers that still use the pc3103/xx (OIS-P) tags from Identec solution (Baumer) wich production were closed down in 2018, we offer customers a refurbishment program that makes the tags as new.The refurbishment program includes: – exchange of battery = prolonged lifetime – test of tags functions – test of micro wave functions. – The program is based on a minimum tag volume of 20 pc per batch or more.We can also offer a wide range of cable ties with LF/HF/UHF tags from HellermannTyton. |

Newsletter

Identification products in Logistics industry 2 – RFID

| In the last newsletter we started our series of Identification products in the Logistics industry and started with barcodes. Now the time has come to RFID technology, which rightly used can be a good complement to barcodes.RFID coded items or positions does not, as is the case with barcodes, need to be in line of sight of the reader and is less vulnerable to dirt or dark locations. Example of this can be placement under a conveyor belt where the labelled items are passing above, embedded in a warehouse concrete floor to register where the ATV, Forklift etc is picking up or delivering an item, labelling a service location for scanning and documentation of services performed etc. |

|

| Our own RFID products and systems suitable for the logistics industry are mainly working in the LF range (125kHz). This range relatively insensitive to its surroundings, working around both water, metal, ice and snow. Reading distances are typically within 50cm which naturally reduces the risk of cross-reading another tag in the vicinity. Another advantage is that the range is less regulated and antennas can be custom made to fit a specific application without needing to be tested and approved – thus allowing a high flexibility in antenna design.We do however also help out customer to whole systems, built around what is best for their application – there are after all times when a HF or UHF system is better suited to solve a particular problem. |

|

| Regarding the RFID tags, we have a large assortment of LF and other tags among our products, such as encapsulated tags for embedding in a concrete floor, small glass tags to embed in tools and machinery, UHF sticker tags for labeling of singer products or packages, even for use in the food industry. We have also tags suited for mounting on a piece of machinery or service location, that is scanned to document when the item is serviced controlled. We will discuss our tags in more detail in a separate newsletter 2 weeks from now. |

Identification products in Logistics industry 1 – Barcodes

Our recent newsletters has to a large part been focused on products and their implementations in the process industry, but they are also well suited for the logistics and warehousing industry. In the coming month, we will present a series of newsletters were we introduce our products in this sector, and how they can be implemented.

We will start in this mail by our EVS138/144 series of barcode readers, and in the next mail we will discuss RFID reader, followed by accessory equipment and implementation services.

Our range of EVS138/144 barcode scanners are ideal for the transportation and logistics sector. Being rugged and robust with a wide reading area, they are suited for both stationary placements as well as mobile on for example a forklift. Our range cover models well suited for outdoor use in strong sunlight where many ordinary readers might have trouble reading the codes, we have also models equipped with LED spotlights for indoor readings in dark warehouses.

|  |

For larger reading ares on a wide forklift mount, two units can be Master/Slave coupled and together work as one wide angle reader, or with each reader working separately to fail proof the reading. For stationary use our readers could be placed by a conveyor belt, reading the codes as they pass by. With a wide reading range, our readers easily pics up codes as they pass by.

For special conditions with hight demands on barcodes robustness, our readers can handle barcodes cut out in metal sheets.

A typical use for our code readers would be for container- or pallet handling and identification, the interface is a standard RS-232 and integrate with most Warehouse management systems.

We can also help customers to a complete system covering handheld barcode reader solutions for portable use through our network of suppliers.

Hide your RFID tags in the floor for forklift position data

When you want positional data for a forklift or similar in the loading dock or factory floor to ensure that the load is taken from the right place, or loaded at the correct container a good idea is to use our floor tag. The floor tag is part of a 125 kHz LF system and designed to be embedded in the floor – out of the way. All that is needed is to drill a small (ca 20mm) hole, drop in the tag and refill the hole.

An LF system is ideal in this case, it both reduces the risk of signals bouncing against the surrounding metal and the risk of reading a neighboring tag instead. We typically install our Ideal125 LF reader in the truck, connected to the trucks terminal wich forward the positional data to the WMS, etc. The antenna is then mounted under the forklift.

As a complement to this positional system. our EVS144 series of code readers can be mounted on the front of the forklift, to id the load and fed back this info to the WMS together with positional data to ensure that the right goods end up in the right position.

Please contact us for more information.

Replacing OIS-L 76/77 in Cimat AGV system

One of our most recent request from a customer was to help them update their old Baumer OIS-L readers whish was beginning to show their age. The update was complicated by the fact that the Tag Data needed to be translated by a resolver database in real-time to positional data for the Cimat AVG:s that were and integrated part of their system. Part of this was also the need to send a tag-in-field signal to their PLC when a tag was in the antenna field for reading.

We solved this by adapting our previous Protocol Converter, make it modular and develop modules where a resolver database, as well as tag-in-field functionality, could be added.

| Ideal125 mounted on custom MPC | Ideal125 mounted on custom MPC |

|  |

The MPC is a further development and merge of our ZIOX host unit and Protocol converter. Following customers needs, it evolved and “MPC” now stands for Modular Protocol Converter – making it possible to add desired functions to the base unit, and thereby simplify the development of customer-specific requests. There are for example a complete keyboard emulator as well as a Tag-In-Field circuit that will send a signal as soon as a tag is within reading distance of an RFID antenna.

The basic MPC still keep the basic functions:

- Bit rate converter that also converts stop/start bits and parity.

- ZIOX-host controller.

Which can be extended with for example

- Logic controller – database with resolver data.

- Keyboard emulation

- Customer-specific modules

- Tag-In-Field circuit that will send a signal as soon as a tag is within reading distance of an RFID antenna

Complementing your TambourID system with our handheld USB reader.

If you have our 134.2 kHz TambourID system installed you might at times have run into a situation when you wanted to read the RFID tag installed on the tambour, but not had any other means to do this except for the fixed installed antennas. You might have suspected that the antenna or reader didn’t perform as it should, or that the tag was damaged and wanted to confirm the TagID or its function through in some additional way.

IdentSystems handheld USB reader can handle the TambourID tags and several other tags in the LF (125/134.2 kHz) range. It can be connected to your normal PC via USB and tag ID is read into the PC for verification. Our USB reader is also powered through the USB port, so no external power is necessary.

The USB reader can, of course, be used in other situations than the TambourID, it is suitable for a range of tags in the 125/134.2 kHz range, so have a look at our international site for details, www.identsystem.com.

If you are from Sweden you can also purchase the reader from our webshop.

USB125 – a handheld reader for control, service and maintenance

Did you know that IdentSystem AB has a small, portable USB LF reader as a complement to our IDEAL125 for fixed montage? USB125 is ideal for control processes in laboratory settings or inventory purposes. It is also well used in service situations as a portable reader in an environment where our IDeal125 reader is fixed installed and where you need a mobile unit for checking readers, inventory, or confirmation of reading data.

It is often used in maintenance: In manufacturing industry tools can be tagged (with for example a small glass tag) to track wear, sharpening and maintenance of press- or stamping tools, drills etc.

USB125 supports the following chips: EM4x02, EM4x50, EM4x05, HITAG1, HITAG2, HITAGS, Q5, TI-RFID which can be found in a variety of tag types, glass tags, Cable tie tags like HellermannTyton, regular disc tags etc.

Contact us for more information about USB125 and tags.

Custom LF RFID antenna solutions

For LF 125 and 134,5 kHz systems, IdentSystem offer our customers the option of having antennas tailor-made for their applications.

Do you need a large antenna that covers a wide area, or maybe a very small to fit in a specific spot? Maybe shaped as a rectangle, square or a circle or to be fitted and screwed in place like a bolt

We can help you with most requests and adapt our antyennas to your needs. We can do this for both our own IDeal125 and IDeal134 (TambourID) systems and the Baumer OIS-L readers. Contact us for more details.

New series RFID cable ties from HellermannTyton

We at IdentSystem AB are to be able to offer our customers the possibility of purchasing HellermannTytons range of RFID tags. Their products consist of plastic or metal cable ties, cradles and hextags – all with embedded RFID tags – from LF, HF and UHF depending on the model.

The cable ties are available in an assortment of sizes and colours (more details soon on www.identsystem.com or www.identsystem.se).

Using cable ties for RFID tagging is an excellent way of marking equipment and tools for tracking, identification, inventory or maintenance purpose, as well as affixing to fixed positions for control, repair and maintenance routines.

The polyamide cable ties is available with HF RFID tag in yellow and 200mm long as well as yellow, black or Light blue as 13,56MHz HF tags.

The stainless steel cable ties can be found as 13,56MHz HF or 869MHz UHF tags at lengths form 201 up to 838mm length – all in red colour.

The cradles are suitable for up to 7,5 mm wide cable ties and are equipped with an HF RFID tag.

For locations or situations when a cable tie is not suitable, there is also the hextag, which can be affixed to a surface by screw, bolt or glued.

More information will be available shortly on www.identsystem.com, or on our swedish webshop www.identsystem.se. If you cannot wait, get in touch with us on Contact@identsystem.com.

Barcode and RFID working in harmony

In some cases, RFID is the most efficient solution to a specific issue, at some times it is barcodes. At other times you might have to use both technologies to make the best outcome for the customer.

Ident System has in a couple of cases successfully combined the technologies in warehouse/logistics settings where the forklift has been equipped with both our EVS138 in a master-slave configuration to increase the reading area and an IDeal125, with an antenna mounted under the forklift to read tags embedded in the concrete floor.

When the WMS process is started, the forklift approaches the pallet to be moved and the RVS138 automatically start scanning for the code and read it- Thanks to the Master-Slave configuration of two EVS138, a large area can be scanned at a distance up to 13 meters. When the code is read the driver will get instructions where the pallet should be delivered on his terminal. This truck-mounted terminal will be communicating with both EVS138 and IDeal125 through an RS232 interface.

When the truck reaches the drop-off location, for example, a container to be loaded, the antenna mounted at the underside of the forklift reads a tag embedded in the concrete floor and either confirm that the correct destination has been reached, or raise a warning that the wrong tag has been read.

This whole WMS process is set so that it is totally automatic, with only input from the driver being when the process is started, right before the pallet is picked up. Closure of the process is done automatically only when the pallet has been dropped off at the correct destination, if the tag at the location is wrong,m the process will not close.